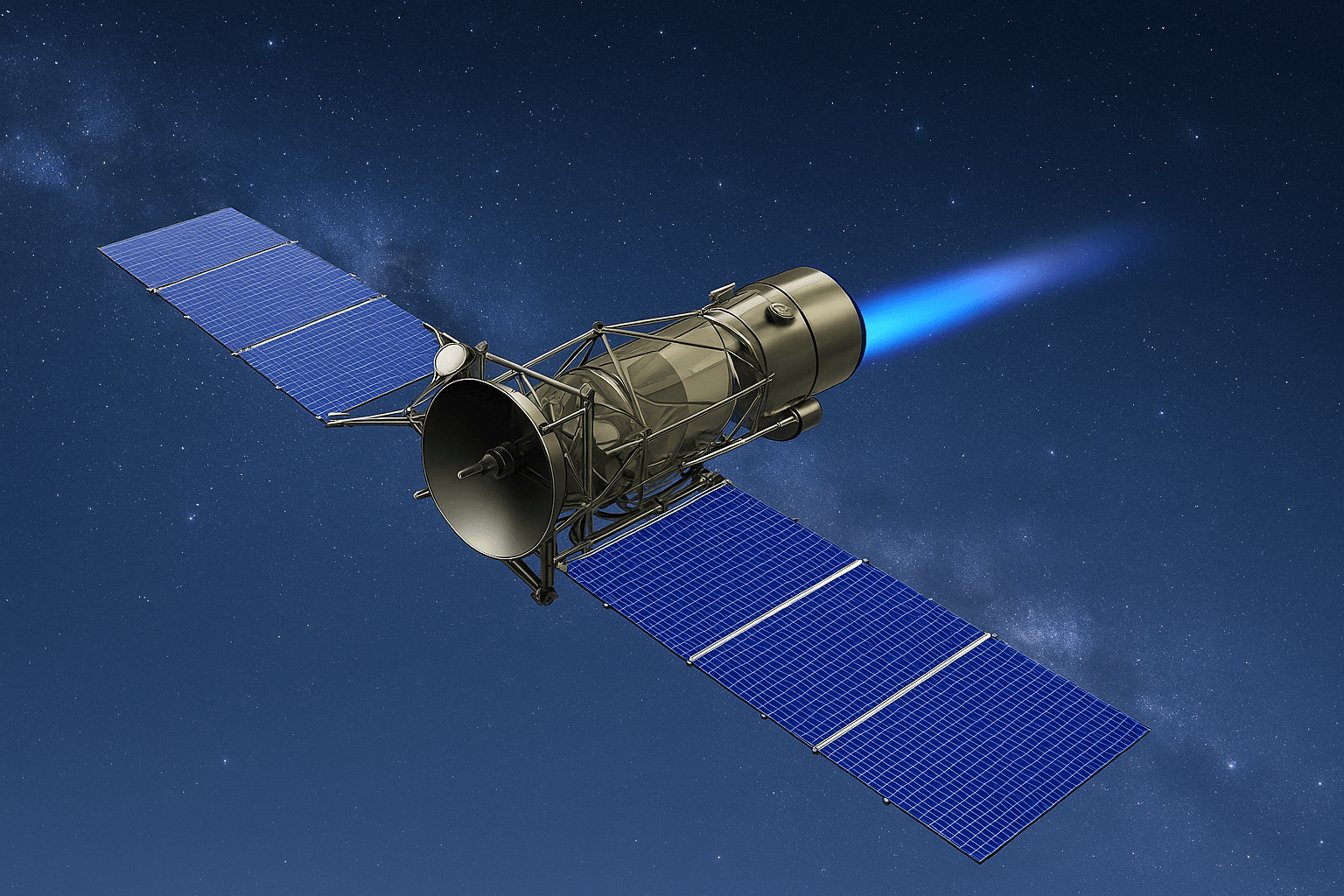

Operational condition maintenance

Our operational maintenance services

Our expertise in operational condition maintenance ensures the availability and optimal performance of your critical equipment.

We offer comprehensive and customized solutions to ensure the continuity of your operations.

- Scheduled and conditional preventive maintenance

- 24/7 emergency corrective interventions

- Equipment modernization and upgrades

- Team training and technical support

Through our proactive approach and advanced diagnostic tools, we optimize the reliability of your installations while controlling your maintenance costs.